Scenario

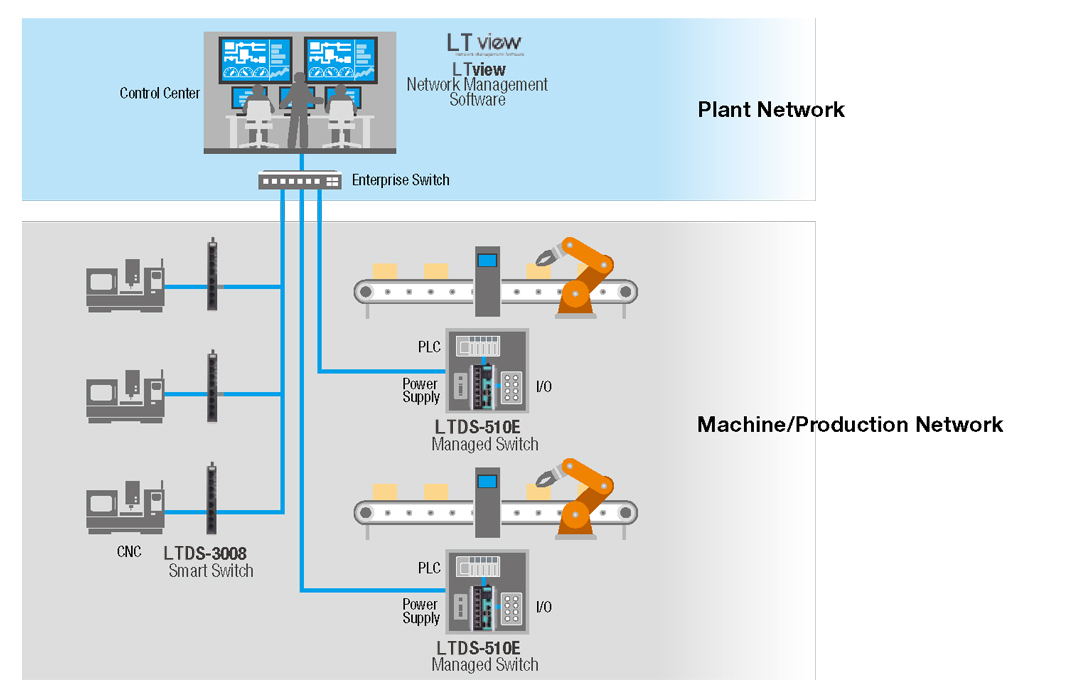

An automotive part manufacturer wanted to digitalise their production processes. The field devices run on the EtherNet/IP protocol for control unification and data acquisition. In order to achieve digitisation, networks had to be interconnected from the field site to the ERP system and to the cloud.

Scenario

An automotive part manufacturer in USA wanted to digitalise their production processes. However, the industrial control networks were built a long time ago and had expanded over time to meet increased production capacity requirements. It became challenging for the company to effectively manage all devices.

The field devices run on the EtherNet/IP protocol for control unification and data acquisition. As this plant required a large-scale network infrastructure, it was difficult for the plant manager to monitor all devices and visualize the network topologies.

In order to achieve digitisation, networks had to be interconnected from the field site to the ERP system and to the cloud. It is essential to have good cybersecurity measures in place to allow this transformation to occur without compromising production efficiency.

Solution

The company upgraded its networks with Langer Techink® industrial managed Ethernet switches that supports EtherNet/IP multicast filtering and advanced security functions. Langer Techink® LTview network management software was also deployed for real-time monitoring and visualisation of the industrial control networks.